Cold Storage Design

Cold room Design.

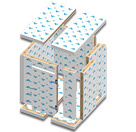

The cold storage body is composed by cold storage bottom packing plate, floor panel, wall panel and top roof panel. The major role of the cold storage bottom plate being laid on a leveled floor is to adjust the level of the floor and to be ventilative, moisture-proof, anti-corrosion and anti-rust.

The base floor panel and wall panel of the cold storage are assembly with different specifications of cold storage panel. The connection between cold storage

panels is by cam-lock, and the joint between panels are affixed to prevent the leakage of refrigeration.

The floor panel is composed of convex-edge base plate, medium base plate and concave-edge base plate.

Same as the floor panel, the roof panel is composed by convex-edge top plate, medium top plate and concave-edge top plate.

The wall panel is divided into two kinds, external wall and inner-cold storage partition wall.

The external wall is composed by angle plate, double-convex wall plate, convex-concave wall plate and biconcave wall plate.

The corner panel is in the cold storages four corners as each whole cold storage has four panel like that.

Each side of wall without a cold storage door must has a double convex wall plate, and the other sides have convex-concave wall plate.

The partition wall is used to separate a cold storage into two compartments, used to reserve different foods.